Strong EV Demand Drives Innovation

You’ve probably read the headlines about the incredible demand for electric cars, driven by increasing gas prices, the desire to reduce our carbon footprints, and the technology in the latest EVs. Ford, who sells more EVs in the U.S. than anyone but Tesla, has seen the greatest demand, especially for its excellent Mustang Mach-E and the F-150 Lightning pickup truck – so much so that waiting lists are hundreds of thousands of vehicles deep.

In order to meet the demand for new electric cars, Ford has announced that it will ramp up production to 600,000 electric vehicles annually by 2023, and more than 2 million vehicles a year by the end of 2026. And it will do so with a new battery technology, lithium iron phosphate (LFP), which it will introduce alongside the nickel cobalt manganese (NCM) technology used in existing vehicles.

Why Lithium Iron Phosphate?

Lithium Iron Phosphate (LFP) cell chemistry has numerous advantages. The most important one is stability of supply – LFP reduces the reliance on scarce critical minerals such as nickel.

Because the supply is more stable, costs are lower, too; Ford estimates a 10-15% savings in material costs versus its NCM batteries.

For owners of Ford EVs, LFP cell chemistry also has minimal range loss over time, a concern with all battery-powered vehicles after many years of use. Ford has not said what percentage of its EVs will eventually use LFP batteries compared to NCM batteries.

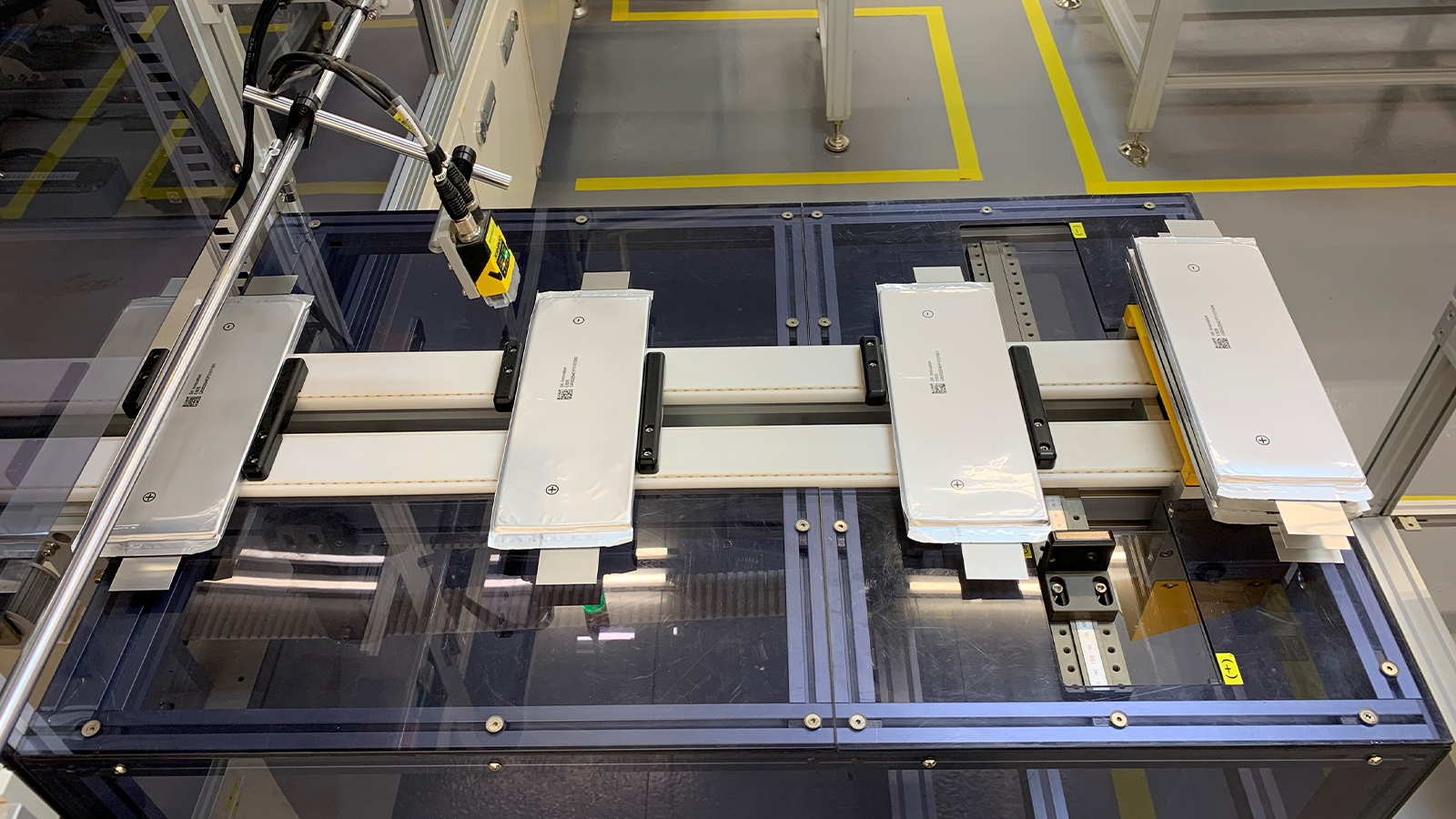

Contemporary Amperex Technology Co., Ltd. (CATL) will provide full LFP battery packs for Mustang Mach-E models for North America starting in 2023, as well as for F-150 Lightnings in early 2024. Ford’s electric architecture flexibility allows the quick integration of LFP technology into these existing vehicles, which means production can ramp up quickly to meet demand.

CATL is one of numerous suppliers Ford is working with. The company also has partnered with LG Energy Solution (LGES) and SK On to meet its battery capacity target for late 2023 – both companies currently supply NCM batteries for the Mach-E, E-Transit, and F-150 Lightning models. Together with all of its partners, Ford says it has secured all of the materials needed to reach its 600,000-unit-a-year electric vehicle goal.

What will those electric cars be? By late 2023, it will consist of 270,000 Mustang Mach-Es for North America, Europe and China; 150,000 F-150 Lightnings for North America; 150,000 Transit electric vans for North America and Europe; and 30,000 units of an all-new SUV for Europe.

Betting Big On Electric

Ford expects a compound annual growth rate (basically, year-over-year sales increases) of over 90% for electric vehicles between 2022 and 2026 – more than double the growth of most industry forecasts. The aggressiveness of its projections is matched by the company’s investment in electric. It will spend over $50 billion on EVs through 2026, by which time it plans on building 2 million electric Fords a year. By 2030, Ford expects 50 per cent of global production being electric, with full carbon neutrality globally by 2050.