BMW Pushes for Hydrogen Fuel Cells

At the start of September 2022, BMW will begin building fuel cell systems at its hydrogen center for competence in Munich. The fuel cells will be used in a small series of BMW iX5 Hydrogen vehicles that will enter service around the world by the end of 2022 for testing and demonstration purposes.

Why Hydrogen?

As the automotive industry continues to push hard towards battery-electric vehicles, BMW is continuing to invest in hydrogen, a technology it has been working on since the late 1980s. The brand has shown both hydrogen-combustion engines, which operate similarly to gasoline engines, as well as hydrogen fuel-cell vehicles. The small series of iX5 Hydrogen SUVs will feature the latter technology, with a fuel cell and a high-performance battery serving electric motors that drive the wheels.

Why hydrogen fuel cells? BMW feels that this unique drive system is well suited for the premium segment, offering rapid refueling as well as lower system weight than a battery large enough to provide long highway cruising range.

“As a versatile energy source, hydrogen has a key role to play on the road to climate neutrality. And it will also gain substantially in importance as far as personal mobility is concerned. We think hydrogen-powered vehicles are ideally placed technologically to fit alongside battery-electric vehicles and complete the electric mobility picture,” said Oliver Zipse, Chairman of the Board of BMW. “By commencing small-scale production of fuel cells today, we are demonstrating the technical maturity of this type of drive system and underscoring its potential for the future.”

Simple and Powerful

Many years of research and development work with hydrogen have helped BMW more than double its fuel cell’s continuous power output, and the second-generation fuel cells fitted to the iX5 Hydrogen are also substantially smaller and lighter. The iX5 Hydrogen’s powertrain delivers 374 hp, roughly equivalent to the gasoline X5. The combination of two hydrogen fuel tanks, the fuel cell, and electric motor packages easily into the existing X5 platform. The company claims the system works very well in winter conditions as well.

In a hydrogen fuel cell, a chemical reaction takes place between hydrogen from the tanks and oxygen from the air. Maintaining a steady supply of both elements to the fuel cell’s membrane is of crucial importance for the drive system’s efficiency. Special hydrogen components unique to BMW’s fuel cell system include a high-speed compressor with turbine and high-voltage coolant pump.

Partnership with Toyota

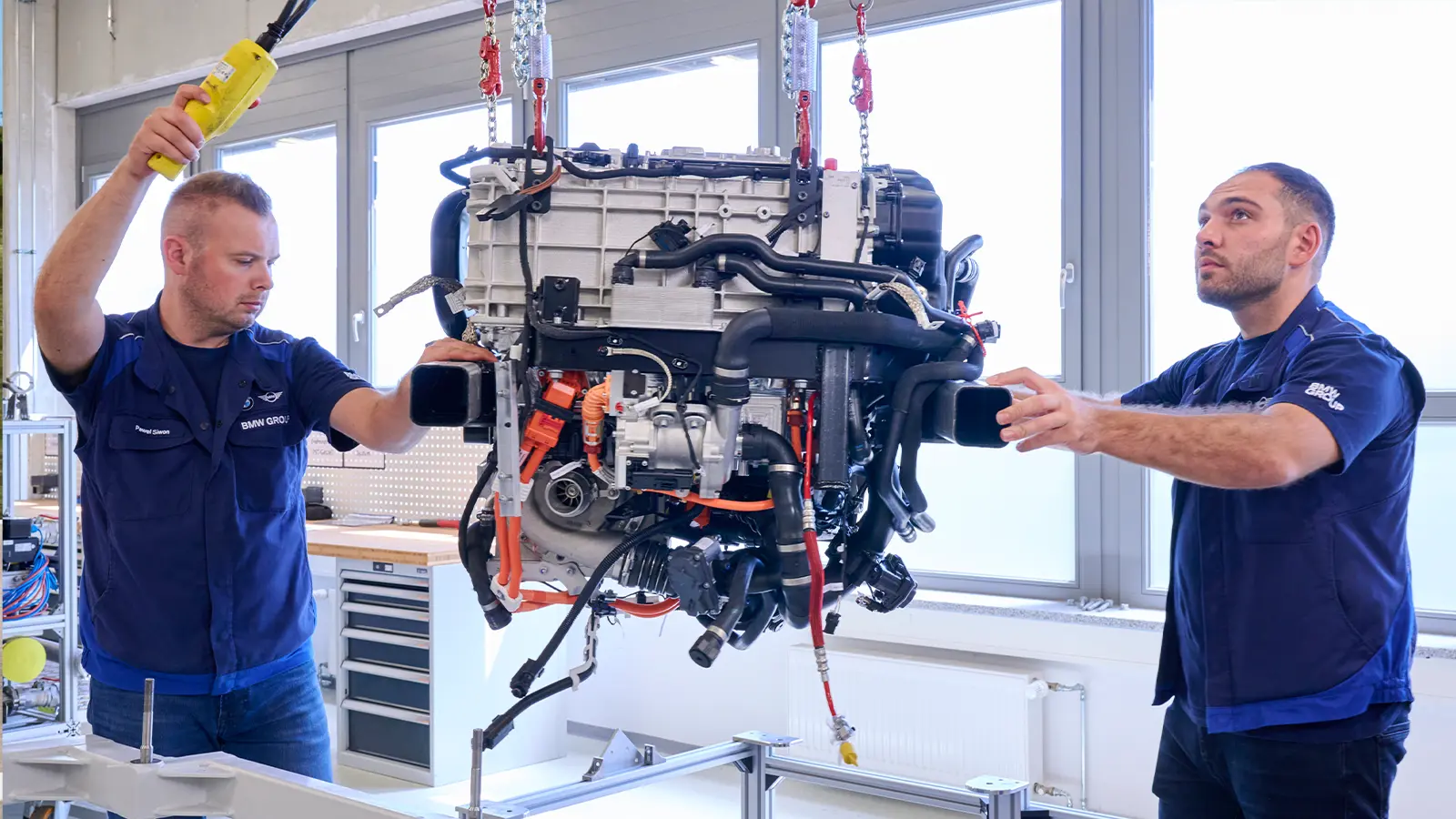

BMW actually sources the individual fuel cells required for manufacturing the BMW iX5 Hydrogen from Toyota. The two companies have enjoyed a partnership for many years, and have been collaborating on fuel cell drive systems since 2013. Fuel cell systems are manufactured in two main steps. The individual fuel cells are first assembled into a fuel cell stack. The next step involves fitting all the other components to produce a complete fuel cell system.

Stacking of the fuel cells is a fully automated process. Once the individual components have been inspected for any damage, the stack is compressed by machine with a force of five tonnes and placed in a housing. The stack housing is manufactured in the foundry at BMW’s Landshut factory using a sand-casting technique. For this, molten aluminium is poured into a mould made from compacted sand mixed with resin. The pressure plate, which delivers hydrogen and oxygen to the fuel cell stack, is made from cast plastic parts and light-alloy castings. The pressure plate forms a gas-tight and water-tight seal around the stack housing.

Final assembly of the fuel cell stacks includes a voltage test along with extensive testing of the chemical reaction within the cells. Finally, all the different components are fitted together in the assembly area to produce the complete system. During this stage, further components are fitted, such as the compressor, the anode and cathode, the high-voltage coolant pump and the wiring harness.

A History with Hydrogen

The performance of the new iX5 Hydrogen is rooted in BMW’s experience with the use of hydrogen as a drive technology. Hydrogen-powered combustion engines had already been in use prior to the arrival of the fuel cell system. Efficiency considerations prompted the company to continue development work on fuel cells with the BMW 5 Series GT Hydrogen Cell. BMW has since refined fuel cells steadily by applying its knowledge of conventional drive technologies and applying the exacting standards of all-round efficiency it expects of all its vehicles.